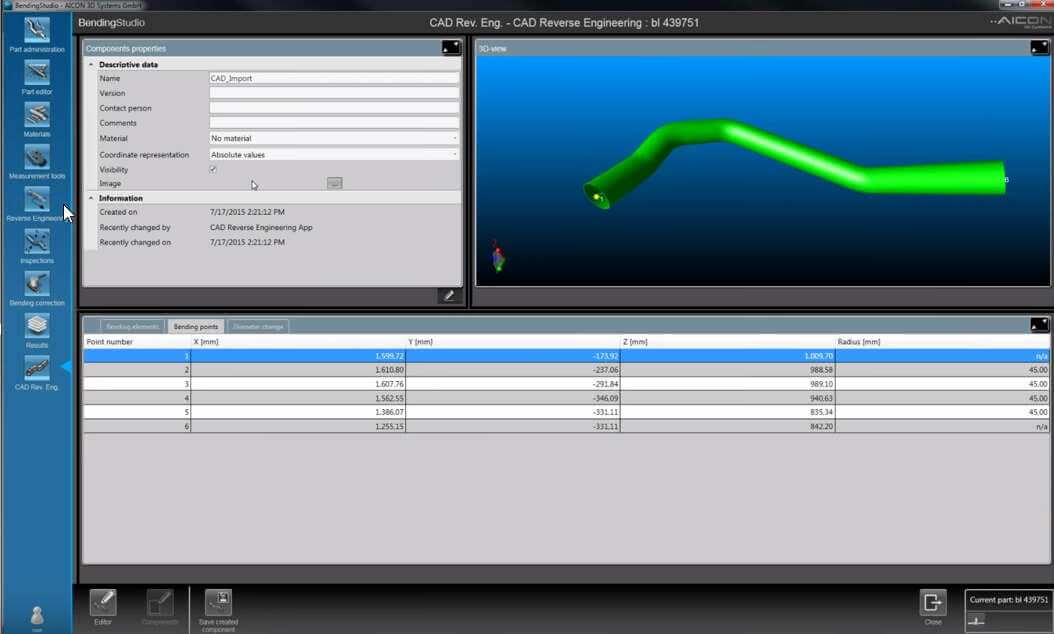

3D Tube Measurement

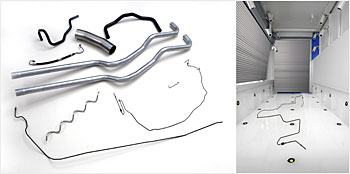

TubeInspect offers better GR&R (Gage Repeatability and Reproducibility), faster cycle times and is much easier to run than conventional measurement systems. Because they identify problems more quickly, efficiency is improved throughout your production; TubeInspect is easier and faster for operators.

Reasons to invest in the TubeInspect System

Faster Feedback.

TubeInspect provides faster feedback after the first part is made on a bender. Comparing the time required to set up and run a part on an articulating arm, the TubeInspect will save between 25% to 75%.First piece setup time

. There are many setup costs that go beyond the operator's cost per hour. Typically there is more than one person working on a setup and machine downtime affects the productivity of the entire plant. Automating the feedback to the bender allows for faster setup times and fewer errors in setup.TubeInspect Speed Reduces Set-up Time

Operators Measure Parts More Easily

TubeInspect Accuracy and Repeatability

- TubeInspect repeatability is usually several times higher than conventional systems.

- Loading of the TubeInspect system consists of placing the tube on the TubeInspect light table. There is no influence from the operator choosing where to measure points.

- Reduced variability in measurement process provides better production control and makes it easier to stay within manufacturing tolerances.

Automation

- Total automation can be accomplished with the addition of a robot holding the tube in the measurement range of the TubeInspect system. The robot does not even need to release the tube while it is being measured.

More Complete Data

- TubeInspect provides complete data through the bend area.

- TubeInspect can measure bend-in-bend tubes which do not have straight sections between bends.

- TubeInspect can measure free-form tubes, 180-degree bends, and small bends.

- TubeInspect will provide overall tube length and by using clip-on adapters will provide data on brackets or other features.

Reliability

- TubeInspect has no moving parts.

- Cameras are permanently mounted on rigid steel supports and are enclosed in a robust housing.

- The light table base is covered by a tough polycarbonate layer.